ETH Zurich scientists revolutionize solar energy with high-efficiency photovoltaic ceramics and advanced solar reactors, producing electricity, hydrogen and synthetic fuels with low environmental impact

For nearly forty years, silicon-based photovoltaic cells have dominated the solar technology market. While silicon solar panels are an excellent renewable resource, significant limitations hinder their widespread adoption. Installing these panels on rooftops can be complex and costly due to the necessary support structures. Additionally, manufacturing silicon cells requires a lot of energy, high temperatures, and limited resources.

These disadvantages have driven research towards new solar technologies that can optimize efficiency, flexibility, and sustainability. A group of engineers from ETH Zurich has developed a photovoltaic ceramic that could revolutionize the industry. ETH Zurich scientists have designed a new ceramic material capable of converting sunlight into energy with an efficiency a thousand times greater than traditional solar panels. This innovation, combined with advanced 3D printing technology, has the potential to completely transform the solar energy landscape.

The photovoltaic ceramic is enriched with a perovskite structure, a metal-organic framework structured in a two-dimensional network. This technology allows for the splitting of water molecules into oxygen and hydrogen thanks to the electric charge generated by light. The produced hydrogen can be stored and used as an energy carrier. This material not only generates electrical energy but also stores chemical energy, offering a superior solution to fossil fuels.

How photovoltaic ceramic works

The ceramic developed by ETH Zurich features an ingenious nanostructure that effectively converts solar energy into electricity. The photovoltaic material consists of aluminum oxide and perovskite nanoparticles, which absorb light and conduct current. Perovskites, known for their excellent light-harvesting properties, are becoming common in solar cells. However, they are generally sensitive to temperature variations, humidity, and mechanical stresses. The ceramic resolves these issues by encapsulating the perovskite nanoparticles in an aluminum oxide matrix.

When exposed to sunlight, the nanoparticles become excited, generating electrons that are transported by the aluminum oxide matrix to the surface of the ceramic, producing an electric current. This photovoltaic ceramic represents an innovation aimed at self-consumption, similar to Tesla solar roofs and mini wind turbines. This invention marks a step forward toward more flexible solar panels adapted to household needs, allowing everyone to save on electricity and move closer to zero impact.

Synthetic solar fuels

In recent years, engineers at ETH Zurich have developed the technology to produce liquid fuels from sunlight and air. In 2019, they demonstrated the entire thermochemical process in real conditions, on the roof of the ETH Machine Laboratory in Zurich. These synthetic solar fuels are carbon neutral, as they release only the amount of CO2 absorbed from the air during their production.

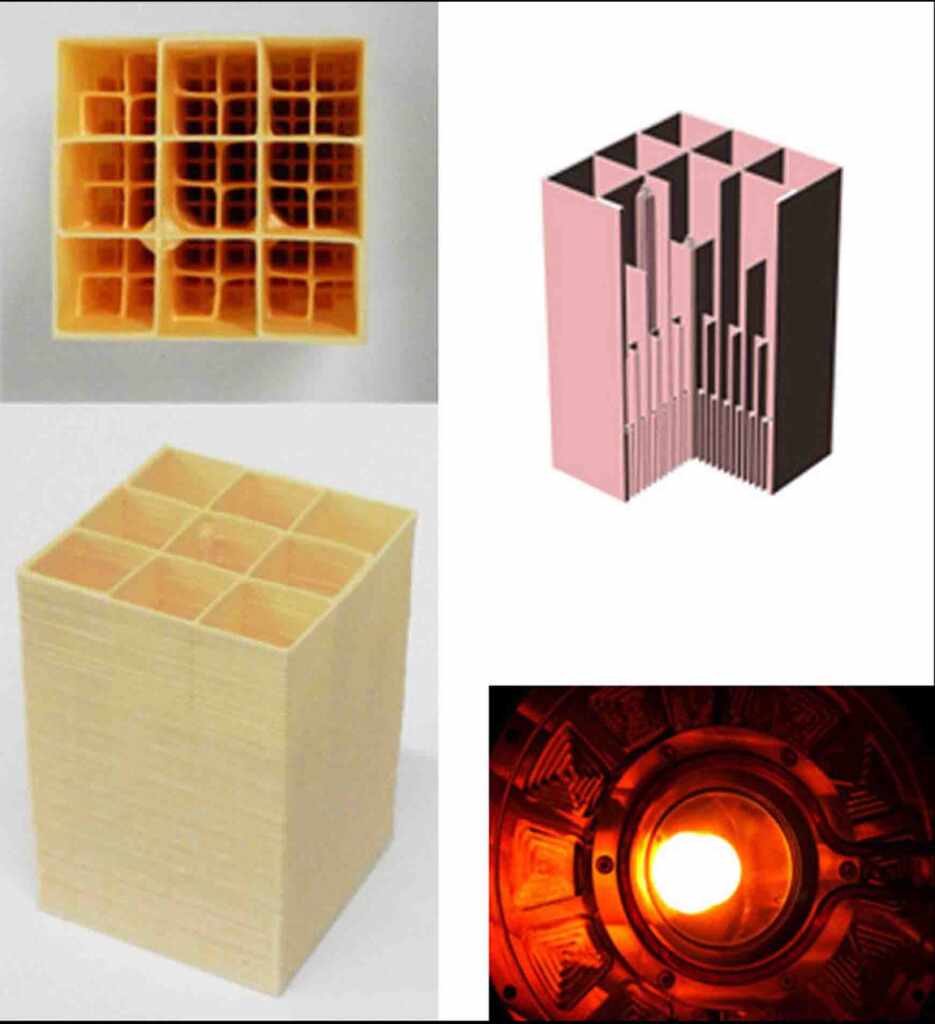

At the heart of the production process is a solar reactor exposed to concentrated sunlight from a parabolic mirror, reaching temperatures up to 2732 degrees Fahrenheit (1500 degrees Celsius). Inside this reactor, containing a porous ceramic structure made of cerium oxide, a thermochemical cycle occurs that splits water and CO2 captured from the air, producing syngas. This syngas can be further converted into liquid fuels like kerosene, usable for aviation.

©ETH Zurich

Innovations in 3D printing

A team of researchers has developed a new type of 3D printing technology that could revolutionize the way we manage solar energy. Traditionally, the porous materials used in solar reactors tended to block part of the sunlight, limiting heat production and thus fuel output. But now, thanks to the work of André Studart, an expert in Complex Materials, and Aldo Steinfeld, a specialist in Renewable Energy, a new method has been created to produce porous ceramic structures that better harness solar radiation.

These new structures are designed with channels and pores that narrow as they go deeper into the reactor, a configuration that allows better capture and distribution of sunlight throughout the reactor’s volume. The result? Internal temperatures can reach up to 2732°F (1500°C), essential for fuel production, and the amount of fuel produced can be doubled compared to traditional systems.

The 3D printing of these ceramic structures uses a special low-viscosity ink, rich in cerium particles, a key element for optimizing solar absorption. The patent for this technology has already been registered, and the company Synhelion has acquired the rights for its commercialization from ETH Zurich. This advancement represents a significant step forward in producing sustainable fuels for aviation, promising to make solar reactors more efficient and economically viable.

Source: ETH Zurich