Scientists have developed a super-fast process for recycling textiles. A chemical process that takes only a quarter of an hour to break down fabrics into reusable molecules

The clothing industry is an ongoing environmental disaster. Each year, the world disposes of over 101 million tons of textiles, most of which end up in landfills or incinerators. Less than 0.5% of these textiles are recycled.

The fast fashion sector contributes the most to this crisis: the massive quantities of secondhand clothes we use and export end up polluting the countries that receive them. But is there a way to turn this situation around?

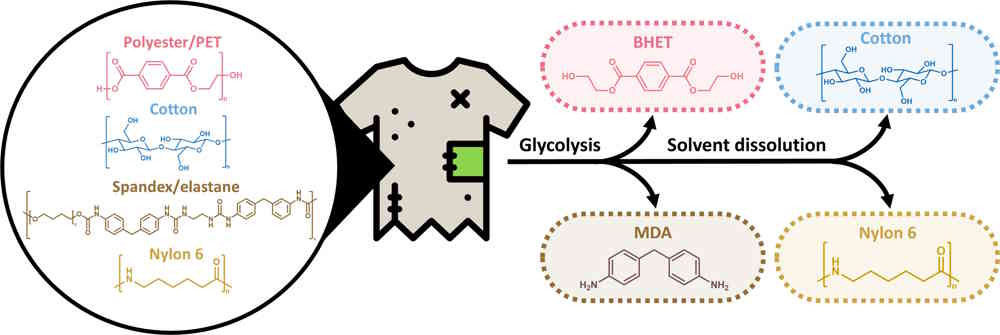

A group of researchers from the University of Delaware has developed a chemical method to address the problem. In a comprehensive study published in Science Advances, they outlined a recycling process that works on fabrics made from various materials. Using a chemical reaction known as glycolysis, they break down the large molecular chains in these fabrics into tiny, reusable units, thanks to heat and a catalyst. These broken-down components can then be used to create new textiles.

The study

Through a process called microwave-assisted glycolysis, scientists broke down the complex polymers in textile waste into reusable molecules.

@Science Advances

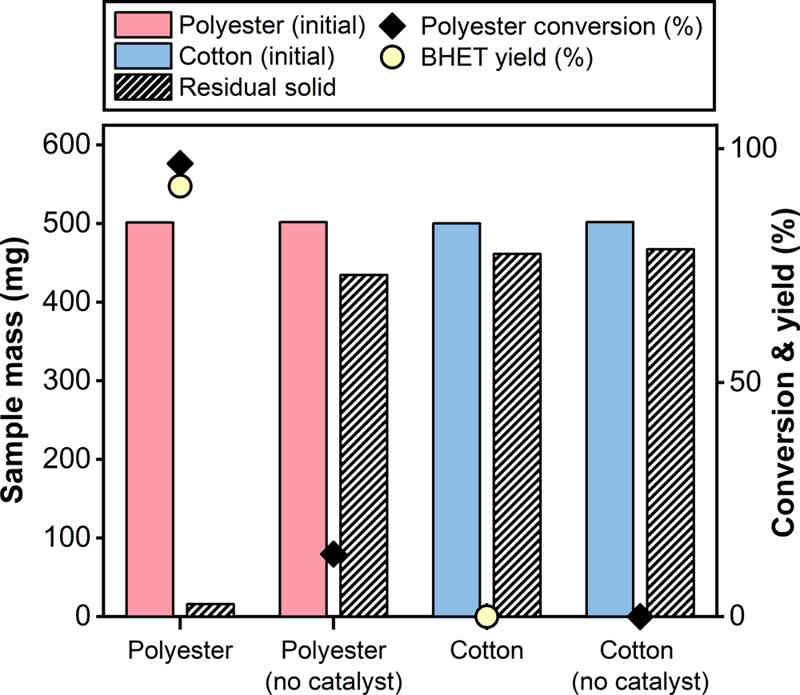

Specifically, they demonstrated a method for managing polyester, cotton, nylon, and spandex in mixed post-consumer textile waste. Under microwave-assisted glycolysis (MW) using a ZnO catalyst, this process took just about 15 minutes to break down the materials.

“We fully degrade polyester and spandex into their monomers, leaving cotton and nylon intact,” the researchers note. They also discussed the effects of textile dyes and finishes, indicating that their study sheds light on chemically recycling mixed textile waste. Further refinement of this process, they suggest, could potentially enable an 88% global textile circularity rate.

The researchers claim the method is simple and inexpensive. However, a challenge remains, as it cannot handle multi-fiber fabrics, additives, or certain dyes, and it reduces fiber length, meaning the recycled material is suitable only for lower-value products like insulation and mattress padding.

Breaking down blends: polyester-cotton and more

In tests involving 100% polyester and 50/50 polyester-cotton fabrics, the glycolysis process converted 90% of the polyester into a recyclable polyester molecule, leaving the cotton intact. Thus, in blended fabrics, polyester could be broken down, while cotton was retained.

@Science Advances

In other experiments, spandex decomposed into a usable molecule, and nylon transformed into recoverable powders.

Further refinement of this process could potentially bring the global textile circularity rate up to 88%, according to the researchers.

Urgency and the growing demand for textiles

This advancement couldn’t come at a better time. Growing populations and increasing global wealth have driven up fiber production demands, with 124 million tons of fiber produced worldwide in 2021. If current trends continue, production is projected to reach 164 million tons by 2030.