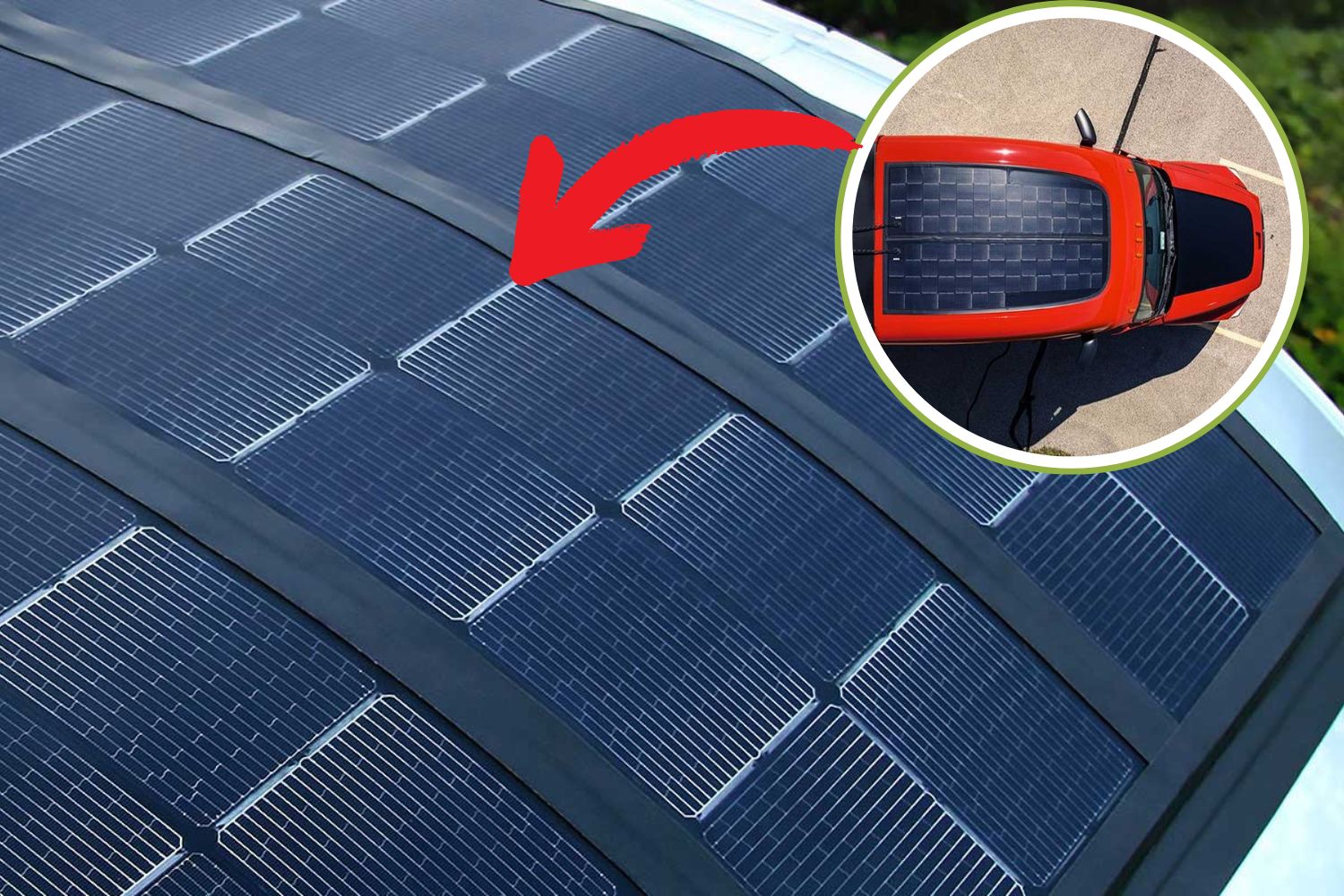

With a conversion efficiency of up to 24%, Merlin Solar's monocrystalline panels stand out for their flexibility and resistance: an innovation that opens up new applications, from vehicles to residential and commercial solar roofs

@Merlin Solar

Monocrystalline solar panels are outstanding in the photovoltaic sector by ensuring better energy conversion efficiency, lying in the range of 16% to 24%. Basically, these panels are made of solar cells made from a single silicon crystal, hence being a bit more powerful compared to the normal polycrystalline panels, which usually try to keep their efficiency between 14% and 18%. While monocrystalline solar cells ensure higher efficiency, structurally they are fragile, which might contribute to affecting their long-term performance and energy output. For this, they need proper encapsulation techniques to be stable and long-lasting.

Improved durability due to metal grids for monocrystalline solar panels

To improve the durability and versatility of monocrystalline panels, Merlin Solar Technologies has developed an innovative approach using metal grids integrated into the cells. This technology increases the number of connections within the cells, making the panels more robust and flexible. This advancement significantly broadens their potential applications, including curved or irregular surfaces.

@MerlinSolar

The integration of metal grids provides several key benefits:

Less structural damage: The lot of interconnections within and between the cells reduce the chance of microfractures.

More resistance to mechanical stress: Panels are able to bear physical stress more effectively.

More optimal performance under partial shading: Energy will be better rerouted when there is shading, making sure power conversion is consistent and energy losses are minimal.

Without this grid technology, monocrystalline panels usually need encapsulation between two layers of glass and mounting into a rigid frame to avoid cracking. But that traditional structure adds weight and makes installation more cumbersome. The panels with metal grids will remain light, allowing for simpler and more flexible installations.

Flexible Applications for Curved and Mobile Surfaces

The incorporation of metal grids has given way to the development of highly flexible monocrystalline solar panels that can be applied on non-flat surfaces. Those panels are not needed to be mounted on rigid support frames and are considered to be perfectly ideal for installations on curved roofs, vehicles, and mobile platforms such as RVs and trucks. They can power onboard devices like refrigerators and lights that help in reducing fuel consumption while traveling.

In addition, such panels are appropriate for residential and commercial lightweight or curved roofs. Their flexibility and lighter weight make their installation easier, which makes them feasible in many applications.