Leaftronics technology, developed inspired by the structure of leaves, offers a sustainable solution to e-waste, with high-performance biodegradable substrates

©Kai Schmidt

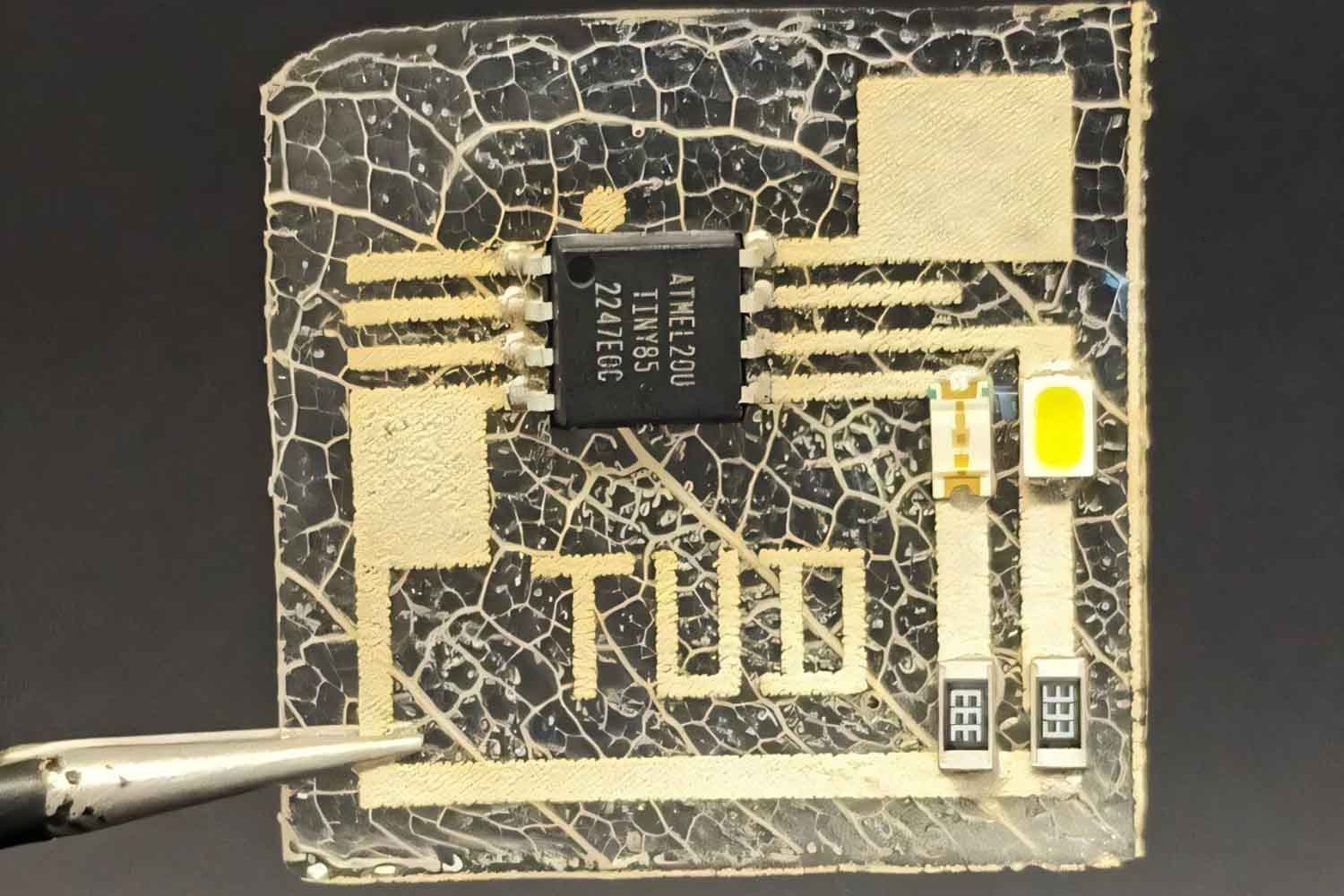

A leaf-so simple, yet so incredibly complex. This humble creation of nature has inspired a revolutionary innovation by a team of researchers led by Prof. Karl Leo at the TUD Dresden University of Technology. The result? Leaftronics is a technology that uses the natural structures of leaves to create biodegradable electronic substrates. These combine high performance with environmental sustainability, offering a way to tackle the growing mountain of electronic waste suffocating our planet.

It represents a breakthrough published in the prestigious journal Science Advances: not some vision of the future, but something rather more tangible-a scalable solution.

E-waste: the global crisis

The world produces over 66 million short tons (60 million metric tons) of electronic waste annually, with more than 75% left uncollected and unrecycled. Much of this comes from non-recyclable substrates, such as fiberglass-reinforced epoxy resin, which forms the backbone of nearly all electronic devices.

For a long time, scientists have tried to find a substitute for such materials using biodegradable ones, but up until now, natural polymers could not bear the temperatures and chemicals needed in industrial production. This barrier is overcome by Leaftronics through one of the smartest designs from nature-the structure of lignocellulose in leaves.

An inspiration of genius: taking biology as the source to innovate technology

The secret to Leaftronics is rooted in a feature of leaves that is usually overlooked. Leaves have lignocellulosic, quasi-fractal skeletons, or highly intricate frameworks, to support living cells. Prof. Leo’s team realized these structures could reinforce biodegradable polymer films to give them thermal and mechanical resilience that previously seemed impossible to achieve.

As Dr. Hans Kleemann, head of the Organic Devices and Systems group, explains:

“The quasi-fractal structures supporting living cells in leaves turned out to be perfect for stabilizing solution-processable polymers. Astonishingly, they maintain these properties even at high temperatures without sacrificing biodegradability.”

This breakthrough not only solves the durability issue but also enables the production of smooth, high-performance substrates crucial for advanced devices like OLEDs (organic light-emitting diodes).

Leaftronics: the green evolution of electronics

Beyond biodegradability, substrates based on Leaftronics have a number of advantages. With a carbon footprint three times lower than paper, they represent a leap forward in energy sustainability. At the end of their life cycle, these substrates can be composted or converted into biogas, allowing valuable components such as metals and semiconductors to be recovered.

This innovation, putting together nature’s brilliance with modern efficiency in technology, can potentially change industries that range from consumer electronics to renewable energy. As Prof. Leo reiterates:

“Leaftronics proves that a fusion of nature and technology is not just an option but an imperative for the environmental challenges ahead.”

The journey toward a truly circular economy depends on ideas like Leaftronics, where advanced technology blends with consideration for the environment. This is beyond waste reduction; it is about how to rethink designing and using electronic devices, placing the centre of attention on harmony with our ecosystem.

Source: Science Advances