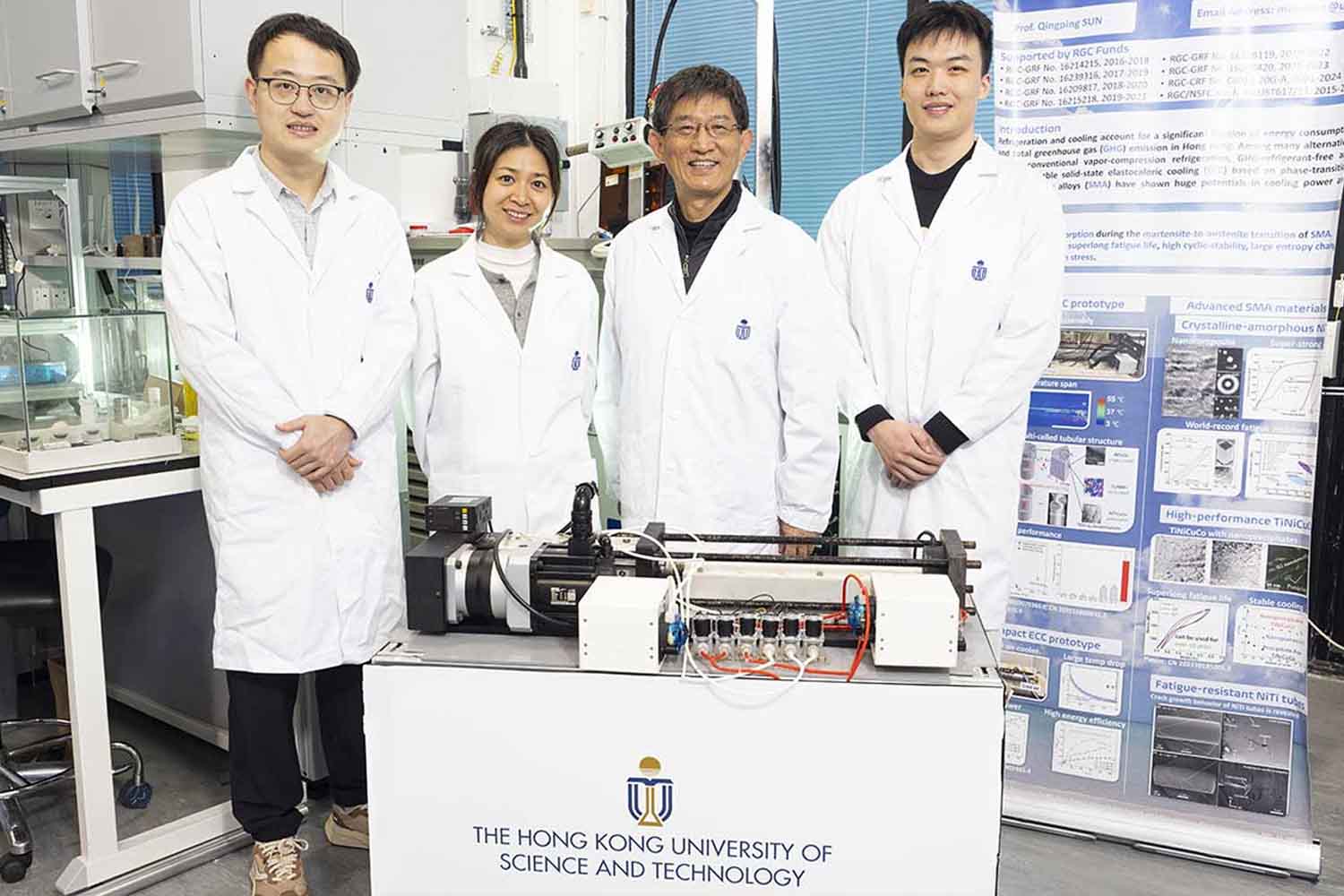

Researchers at the University of Hong Kong have developed an elastocaloric air conditioner capable of cooling rooms without polluting refrigerants

©HKUST

Air conditioning now accounts for about 25% of energy use in buildings—and that number is rising, driven by climate change. Traditional air conditioners not only consume massive amounts of energy but also rely on highly polluting refrigerants. But a groundbreaking innovation could be a game-changer: using elastocaloric materials to eliminate the need for conventional coolants altogether.

The elastocaloric effect is a thermomechanical phenomenon in which certain materials change temperature when mechanically stressed. A research team from the Hong Kong University of Science and Technology (HKUST) has just announced a major leap forward that could redefine the future of cooling systems.

Until now, elastocaloric cooling systems were limited to less than 1 kilowatt of power, making them impractical for room-scale applications. But a new device developed by Professors Sun Qingping and Yao Shuhuai at HKUST breaks that barrier, showing that it’s now possible to cool entire rooms with impressive efficiency.

The breakthrough, detailed in Nature Energy, suggests this technology could help cut carbon emissions while transforming how we cool our spaces. It builds on earlier work by the same research group.

A multicellular design to boost cooling performance

One of the biggest challenges in elastocaloric cooling was finding the right balance between cooling power and the total mass of active materials, as well as dealing with inefficient heat transfer at high frequencies. To overcome these issues, the researchers designed a multicellular structure made up of ten elastocaloric cooling units connected in series.

Each unit contains four thin nickel-titanium alloy tubes, carefully engineered to optimize heat transfer. This modular design led to a dramatic leap in performance.

Unlike earlier versions that used distilled water, this system employs graphene-based nanofluids, further improving efficiency. In lab tests, the prototype achieved a specific cooling power of 12.3 watts per gram at 3.5 Hz, delivering a total cooling output of 1,284 watts—the highest ever recorded for this type of technology.

During real-world trials, the system successfully cooled a room measuring 81 cubic feet (2.3 cubic meters), stabilizing indoor temperatures between 69.8°F and 71.6°F (21–22°C) within just 15 minutes, even while outdoor temperatures hovered between 86°F and 87.8°F (30–31°C).

This innovation proves that elastocaloric cooling can scale

“This innovation demonstrates that elastocaloric cooling can be applied on a large scale. We are working with industry partners to accelerate commercialization. With increasingly strict global regulations on hydrofluorocarbons (HFCs), this zero-emission, energy-efficient technology is poised to transform the air conditioning sector and support carbon neutrality goals.”

— Professor Sun Qingping

With global pressure mounting to reduce HFC emissions, this breakthrough could not have come at a better time. Scalable, high-performance, and free of traditional refrigerants, elastocaloric cooling could be the future of climate-friendly air conditioning.

Source: HKUST