A research team has developed an innovative method for depolymerizing PET, using an engineered thermophilic bacterium: with an efficiency of 96.7%, it represents a major breakthrough for sustainable plastic waste management and the circular economy

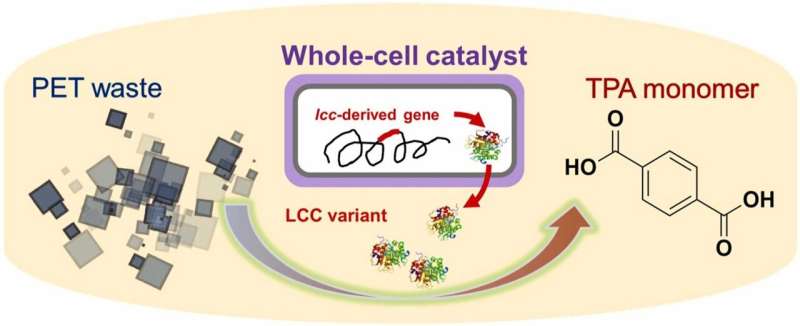

Researchers have come up with a groundbreaking technique for depolymerization of polyethylene terephthalate (PET) using a whole-cell biocatalyst derived from the thermophilic bacterium Clostridium thermocellum. Their study, published in the Journal of Hazardous Materials, shows a PET conversion yield of 96.7%, indicating the promising nature of this technology in the eradication of plastic pollution and the establishment of a circular economy.

PET, the most widely used plastic polymer and petroleum-based, is a critical environmental issue since it is non-biodegradable and finds its way into landfills. Therefore, there is a need to maximize PET recycling to reduce petroleum usage, carbon emissions, and plastic waste’s impacts on the environment.

Advantages of whole-cell biocatalysis in plastic recycling

Much of the PET recycling research has been in terms of the creation of degrading enzymes, but whole-cell biocatalysis is now an increasingly viable option. This is a process that offers several advantages like in situ enzyme production, simple processes, and high efficiency at industrial scale.

The new study is a follow-up of previous work reported in Microbial Biotechnology, where the group had demonstrated that PET depolymerization was feasible at high temperature using genetically engineered Clostridium thermocellum. The microorganism was induced to express leaf-branch compost cutinase (LCC) through a plasmid.

In this new paper here, the researchers maximized their approach by directly introducing the LCC gene into the bacterium’s chromosome for even more stable expression of enzymes. Additionally, they supported LCC mutants and co-expressed hydrophobic modules for further process optimization.

Through optimal control of reaction conditions and precise regulation of pH, the team was able to minimize the formation of byproduct mono(2-hydroxyethyl) terephthalate (MHET), thereby achieving significantly higher yields of depolymerization.

Toward a sustainable and efficient PET recycling process

@Journal of Hazardous Materials

When PET bottle scraps pretreated with this process, the scientists achieved a 97% conversion into terephthalic acid (TPA), a prominent monomer to produce new plastic or valuable chemicals. This tremendous efficiency indicates the potential of the technology as a high-tech environment solution for recycling PET.

Another advantage of the system is the native ability of Clostridium thermocellum to degrade cellulose, offering itself as an ideal candidate for treatment of mixed textile waste with both cotton and PET.

The study was conducted in partnership with the Chinese Academy of Sciences’ Qingdao Institute of Bioenergy and Bioprocess Technology, Nanjing Tech University, and Greifswald University, a significant step toward a greener future.

Source: Journal of Hazardous Materials