A new sewage sludge conversion system reduces CO₂ emissions by 99.5% compared to traditional methods, turning waste into food and clean fuel

©Nature

Every city in the world inevitably produces sewage sludge, the dense organic residue generated by wastewater treatment. This mass accumulates at a staggering rate, with over 220 million tons of dry sludge produced globally each year. The disposal of this sludge is expensive and complicated: it can contain organic substances, nutrients like nitrogen and phosphorus, as well as heavy metals and toxic compounds. Currently, the most common disposal methods are incineration, which releases harmful substances, or composting, which, however, takes a very long time.

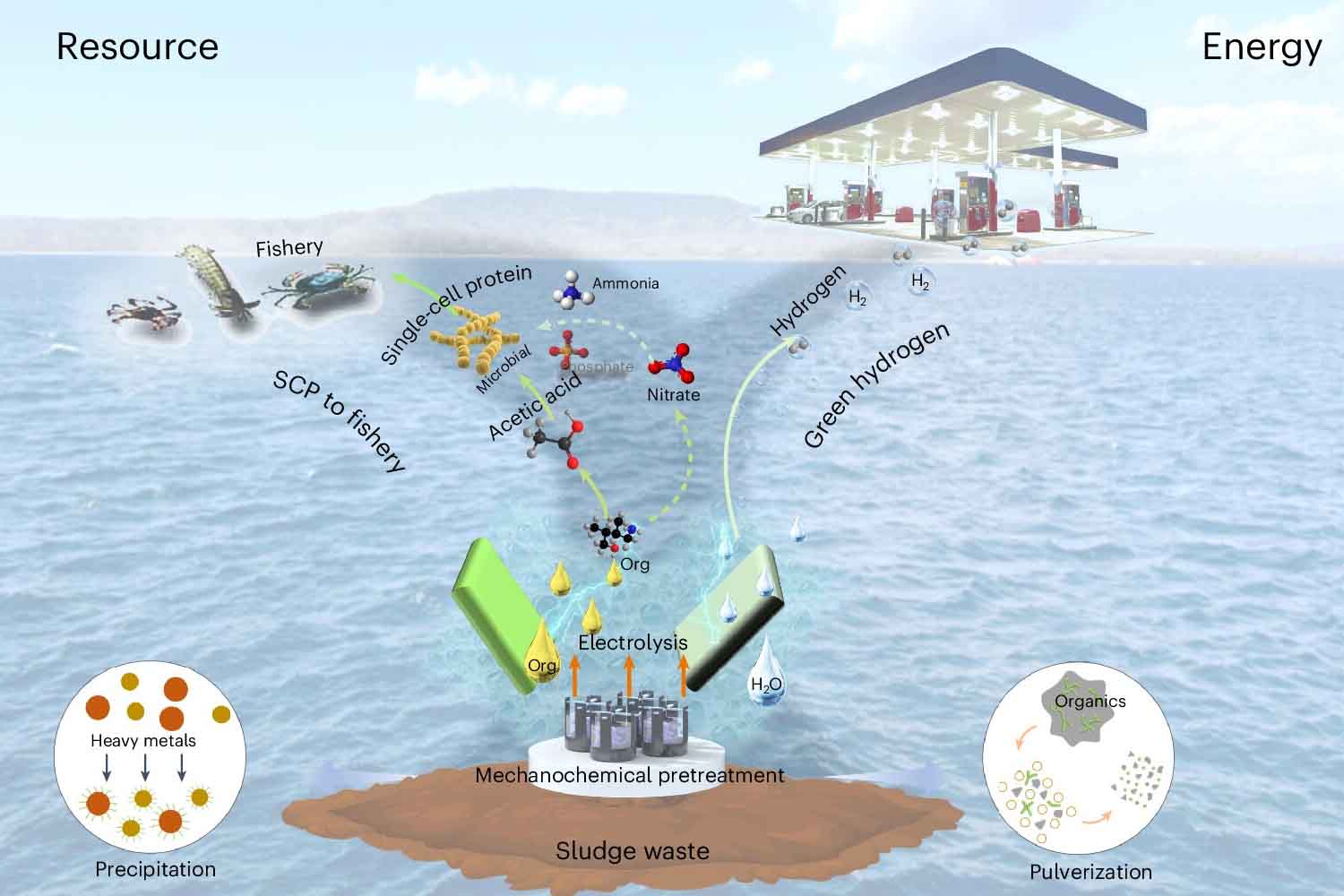

Now, however, a new discovery could radically change the management of this waste. A team of scientists from Nanyang Technological University in Singapore has developed a groundbreaking system that transforms sewage sludge into two valuable resources: single-cell proteins, usable as animal feed, and green hydrogen, a clean fuel. The research, published in Nature Water, paves the way for a more sustainable model of urban waste management.

How the new sewage sludge conversion method works

The process developed by the researchers consists of three key stages, utilizing advanced technologies and renewable solar energy.

Mechanical-chemical decomposition: The sludge undergoes intensive grinding with the addition of an alkaline catalyst (such as potassium hydroxide). This treatment breaks down the molecular structure of the material, allowing for the separation of useful components while trapping heavy metals in a solid, safe form for disposal.

Electrolysis and green hydrogen production: The dissolved organic matter is treated through an electrolysis system powered by solar energy. This is where the key transformation happens: instead of simply degrading, the organic material undergoes electrochemical oxidation, leading to the formation of volatile fatty acids, particularly acetic acid, an essential element for microbial biomass production. Meanwhile, at the cathode of the system, water is broken down to generate green hydrogen, a clean fuel with enormous potential for the industrial and transportation sectors.

Protein production through phototrophic bacteria: The acetic acid and other compounds generated are then used as nutrients for purple phototrophic bacteria, which are capable of converting organic matter into single-cell proteins. These proteins can be used as animal feed, providing a sustainable solution for the livestock industry.

A revolutionary environmental impact

The idea of reusing sewage sludge is not new, but the results achieved with this system are extraordinary. 91% of the organic carbon in the sludge is recovered and converted into useful products, while 63% of the total carbon is transformed into proteins.

However, the most surprising aspect concerns CO₂ emissions, which are reduced by 99.5% compared to traditional treatment methods such as anaerobic digestion.

The main question now is: can this technology be applied on a large scale? According to Dr. Zhao Hu, the lead author of the study, the answer is yes. The system is designed to be modular and adaptable, able to be integrated into existing treatment plants without the need for costly infrastructure modifications. This means it could be implemented in both large metropolises and smaller urban centers, offering an eco-friendly alternative to waste management.

With the continued growth of the global population and the acceleration of urbanization, the problem of sludge disposal is becoming increasingly urgent. This innovative method could represent a game-changer, turning an environmental problem into a valuable resource.

If adopted globally, it could redefine the very concept of waste, transforming the superfluous into value and significantly reducing the ecological impact of cities. The future of sustainability could very well begin with sewage sludge.

Source: Nature