From high atmospheric concentrations of CO2 to new sustainable solutions: MIT created an electrode that converts carbon into ethylene and other compounds

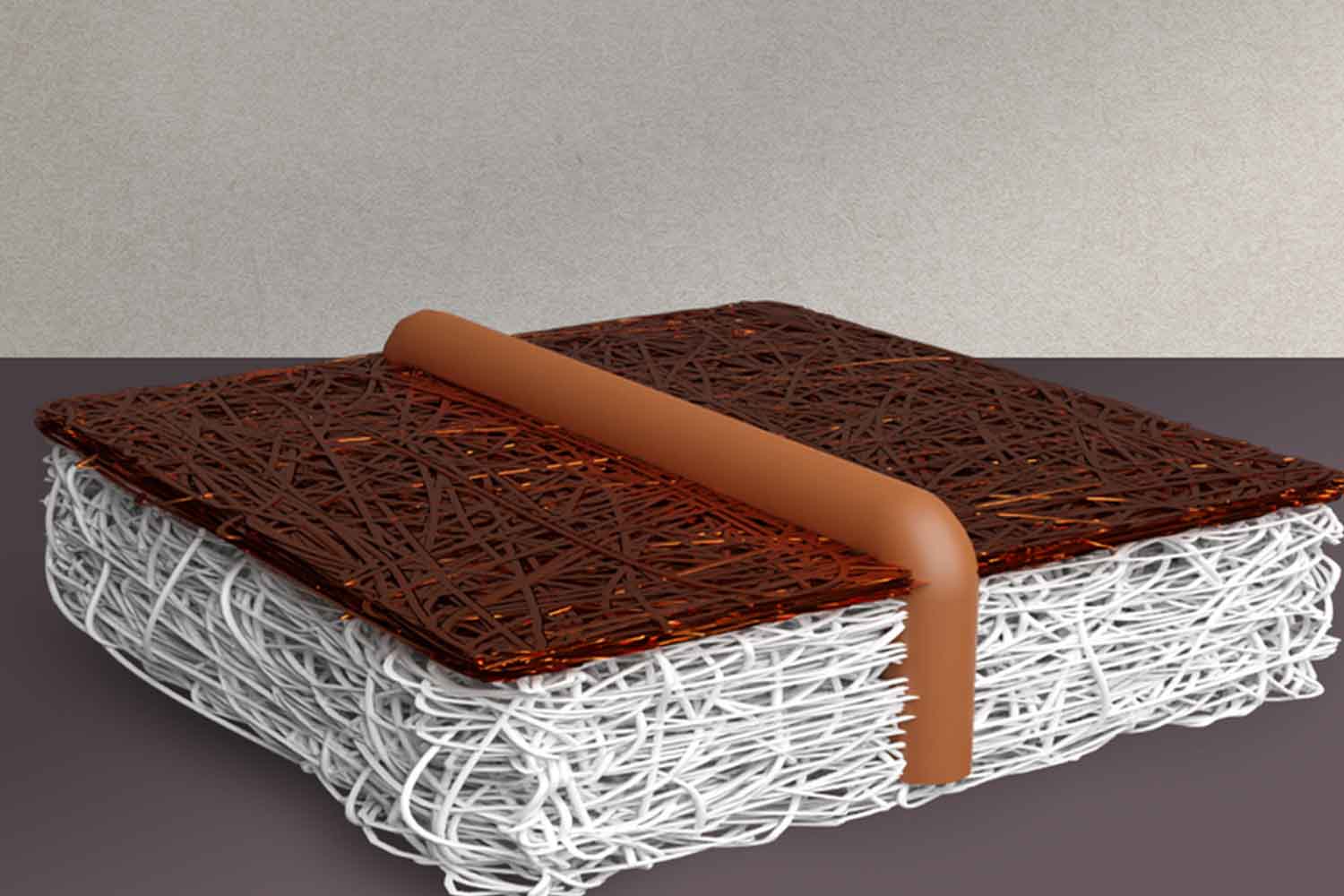

©MIT

According to the United Nations, carbon dioxide in the atmosphere reached a record-high level of 420 ppm in 2023. Mitigating the effects of extra CO2 on the global climate requires not only a reduction in emissions but also effective ways of capturing and converting this gas into something useful. Among the emerging solutions, a new technology developed by researchers at MIT uses a Teflon and copper-based electrode to convert CO2 into things like ethylene.

Cutting-edge engineering: the MIT technology

Amazing technology that demonstrates the advancedness of engineering at MIT leverages a gas diffusion electrode comprising a water-based electrolyte and a catalytic material. Designing such an electrode that would effectively possess excellent electrical conductivity together with hydrophobicity presented a big challenge. It took months of trial before finding the best solution-using PTFE, popularly known as Teflon for hydrophobicity and integrating it with finely stranded copper wires woven around it to enhance conductivity.

From CO2 to ethylene: industrial applications and economic potential

The MIT electrode enables the conversion of carbon dioxide into ethylene, a key chemical compound used in producing fuels and plastic materials. This process, based on electrochemical conversion, could also extend to the production of other valuable substances, including methane, methanol, and carbon monoxide. Given that the average price of ethylene in 2023 was around $930 per ton, according to Statista, this technology could have a significant economic impact. It offers a more profitable alternative to current carbon storage costs, which range from $44 to $220 per ton, as reported by Ifri.

Initial prototypes of the electrodes, measuring about 1 inch (2.5 cm), revealed an important correlation between the device size and its efficiency. Tests on larger electrodes then proved that conductivity decreases as the system is scaled up. In order to address this issue, the researchers were able to calculate the optimal spacing between copper wires-a strategy to improve the performance of large-scale applications.