Breakthrough innovation could solve one of nuclear fusion's biggest problems: Thanks to 3D printing, fuel capsules can be produced on a large scale

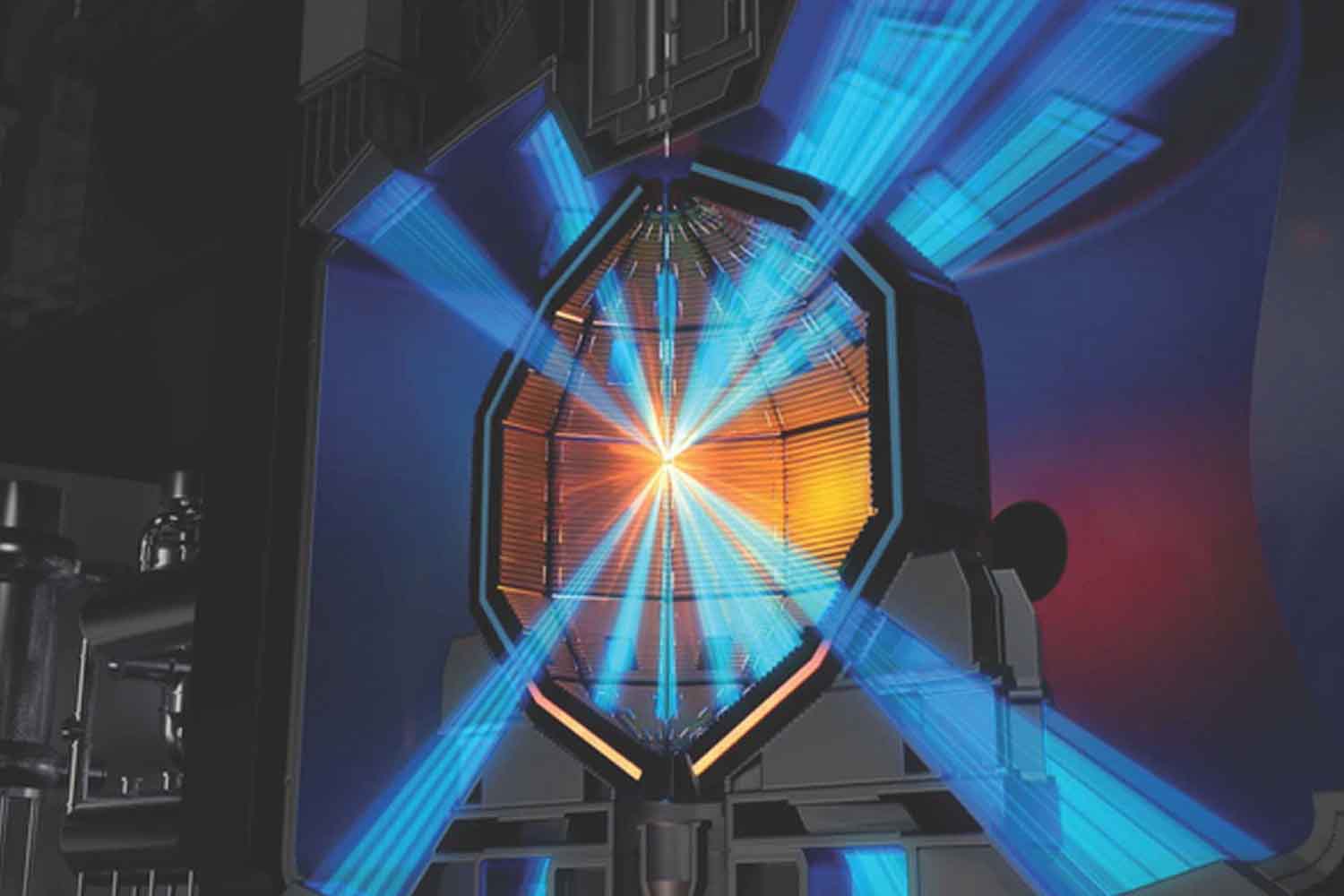

©LLNL

Nuclear fusion, the long-awaited solution to an infinite and sustainable energy future, has always been hindered by a single technological hurdle: fuel capsule manufacturing. Now, revolutionary technology developed in the United States stands ready to finally overcome the obstacle, accelerating the arrival of commercial fusion energy.

3d-printed fuel capsules revolutionize production

At Lawrence Livermore National Laboratory (LLNL), researchers have discovered a novel method for manufacturing fuel capsules, the essential components that must be created in order to initiate the fusion reaction. To date, their manufacture has been sluggish, expensive, and relatively inefficient. But with 3D printing, this could all change.

Why are fuel capsules so important?

Inside these capsules is tritium and deuterium, two isotopes of hydrogen that, when exposed to high heat, trigger the fusion reaction—the very reaction that powers the Sun. But why is this discovery so significant?

The challenge here is that these capsules must be precisely spherical with a very high level of precision in order to maximize efficiency in the process. It can take months to make one capsule today, while a commercial fusion power plant would require more than a million capsules per day. Using traditional methods, it was not possible to meet this requirement.

To overcome this limitation, LLNL researchers have created a new 3D printing technique called dual-wavelength two-photon polymerization (DW-2PP). This new technology enables the production of highly precise capsules with complex geometries and microscopic features at high speed.

What are the benefits of this new technology?

The benefits of this innovation are enormous:

- Massively reduced production times, making large-scale production feasible

- Much higher precision, with perfectly spherical capsules for higher efficiency

- Lower costs, making nuclear fusion financially more viable

- A more sustainable process than traditional manufacturing methods

This technology, if realized on a broad scale, would be a game-changer toward commercial nuclear fusion, reducing costs and making this energy a tangible reality.

In 2024, the first capsules produced by this method were successfully tested at the National Ignition Facility (NIF). This outcome confirms the potential of this breakthrough and could potentially cut the development time for nuclear fusion drastically.

Despite challenges remaining, the progress is unmistakable. With faster and more efficient development, the dream of clean, safe, and limitless fusion energy could be here sooner than expected. LLNL’s breakthrough is a history-making milestone, showing that the future of sustainable energy is now no longer a vision but an increasingly realistic goal.

Source: LLNL